Because the target condition lies beyond the reach of our flashlight, the path to attaining it cannot be predicted with exactness. Thus, we have to find that path by experimenting. This is the scientific method, which consists of formulating hypotheses and then testing them with information obtained from direct observation.

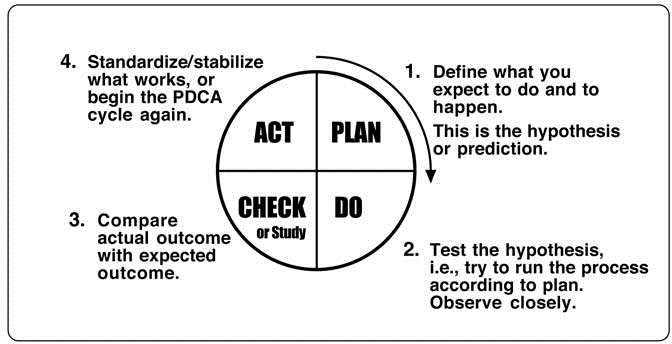

The procedure or steps of experimentation are summarized by the well-known Plan-Do-Check-Act cycle (Figure 6-6):

- Plan. Define what you expect to do and to This is the hypothesis or prediction.

- Do (or Try Out). Test the hypothesis, that is, try to run the process according to plan. This is often done on a small scale Observe closely.

- Check (or Study). Compare the actual outcome with the expected

- Act (What’s next?). Standardize and stabilize what works, or begin the PDCA cycle

Figure 6-6. The PDCA cycle

The steps of PDCA constitute a scientific process of acquiring knowledge. PDCA provides us with a practical means of attaining a challenging target condition—it is the means for getting through the gray zone and characterizes a learning organization. But only if we use it the right way.

PDCA may have been introduced to the Japanese in the 1950s via lecture courses given in Japan by W. Edwards Deming, although at that time the terminology “PDCA” was probably not in use and Deming likely presented a version of the Shewhart cycle. This was Walter A. Shewhart’s circular, or spiraling, depiction of “steps in a dynamic scientific process of acquiring knowledge,” which appears in Shewhart’s 1939 book Statistical Method from the Viewpoint of Quality Control. It is also certainly conceivable that persons in Japan already knew of Shewhart’s writing and were familiar with the scientific method.

During his 1950–52 lecture activities in Japan, Deming provided training for engineers and statisticians, and gave lectures for top management. It is interesting to note that he presented the statistical techniques as management tools and emphasized overall managerial concepts like the Shewhart cycle. In other words, Deming’s lectures

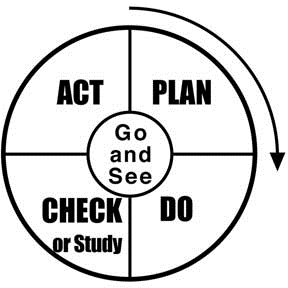

Figure 6-7. Toyota added Go and See to the center of the PDCA cycle

were delivered in the context of a way of thinking and managing, rather than simply as techniques. This is clearly also the fashion in which Toyota adopted PDCA, where it became a strategic approach and a basis for improvement and leadership at all levels.

Toyota later added the words “Go and See” to the middle of the PDCA wheel (Figure 6-7), because Toyota considers this to be important in all steps of PDCA. No matter how confident you are, you must always go and see the actual condition for yourself in order to understand it, because the situation is always changing as you move forward. If you were to only go and see one time, for example, you would become progressively more removed and distant from the real situation.

The words spoken most often at Toyota may well be, “Show me.” I came across a good example of the necessity to go and see at an assembly process in Portugal. The engineers in the office said they knew from their calculation of machine capacities which workstation was the bottleneck in the assembly process. However, in the actual process on the shop floor, an entirely different workstation was the current bottleneck. The current real situation and problems in the process were not the same as those the engineers in the office were assuming based on their data. This is the reason that Toyota makes a distinction between facts and data, and prefers facts over data wherever possible.

Key Points About PDCA

We have known about PDCA for a long time, but we are not yet using it as does Toyota in its improvement kata. To start developing a deeper understanding, consider the following four points from the arena of scientific experimentation, discovery, and learning.

- Adaptive and evolutionary systems by their nature involve experi Since the way ahead is a gray zone, if we want progress, we must experiment. A target condition, for example, is only a setup for conducting experiments.

Hypotheses are nets: only he who casts will catch.

—Novalis (Friedrich Freiherr von Hardenberg) as quoted in

The Logic of Scientific Discovery, by Karl Popper

- Hypotheses can only be tested by experiment, not by intellectual discussion, opinion, or human This is what I call testing over talking. When you hear statements like, “I believe . . .” or “I think . . .” it is often better to stop talking and take a step; to test as quickly as possible, usually on a small scale first, so you can see further based on facts and data.

Neither the voice of authority, nor the weight of reason and argument are as significant as experiments for thence comes quiet to the mind.

The moment of experience is the firmest reality.

—Roger Bacon

—Composer Benjamin Boretz

- In order for an experiment to be scientific it must be possible that the hypothesis will be This point is a little more difficult to understand, but it gets us closer to what Toyota is doing. The visiting executive who reviews an assembly process’s heijunka leveling scheme and simply nods his approval, as mentioned in the last chapter, rather than asking, “What is currently preventing you from operating this way?” has not yet internalized this point. Neither has the plant manager who is planning to implement pull systems across his entire 6,000-person facility.

If we assume that at any time anything we have planned may not work as intended, that is, that it is always possible that the hypothesis will be false, then we keep our eyes and minds open to what we learn along the way. Conversely, if we think everything can work as planned, then we too easily turn a blind eye to reality—like the engineers at that factory in Portugal who thought they knew what the process bottleneck was—and tend to simply push for greater discipline in carrying out the plan. If we expect that everything can work as planned, then the effect is that we stop improving and adapting.

The game of science is, in principle, without end. He who decides one day that scientific statements do not call for any further test, and that they can be regarded as finally verified, retires from the game.

—Karl Popper

- When a hypothesis is refuted this is in particular when we can gain new insight and further develop our Envision a scientist in a laboratory wearing a white lab coat and heavy gloves, who is slowly pouring two beakers of clear liquid together under a fume hood. The scientist has predicted that combining these liquids will produce a blue liquid. If the resulting mixture does, in fact, turn blue, then the experiment was a confirmation of something the scientist already believed, and the scientist has not really learned anything new. If a hypothesis is not refuted, then the experiment was only a confirmation of already held ideas. Or, put in other terms, if there is no problem, there is not much improvement.

On the other hand, if the mixture of the two liquids explodes and the scientist is covered in ash and holding two cracked beakers—an unexpected outcome—then he is about to learn something new.

Problems cannot be solved at the same level of awareness that created them.

—Attributed to Albert Einstein

There is no such thing as a failed experiment, only experiments with unexpected outcomes.

—R. Buckminster Fuller

We learn from failures because they reveal boundaries in our system’s current capability and horizons in our minds. This is why Toyota states that “problems are jewels.” They show us the way forward to a target condition. You need to miss the target periodically (again, preferably on a small scale that does not affect the customer) in order to see the appropriate next step. This is a fascinating point when you consider how much we as leaders, managers, and executives try to make it look like everything is going right and as planned. The main reason for conducting an experiment is not to test if something will work, but to learn what will not work as expected, and thus what we need to do to keep moving forward.

Learning to Ask a Different Question

As we take steps toward a target condition, one comment you sometimes hear is: “Let’s see if this will work.” This, erroneously, seems like a reasonable question since we are talking about experimenting. However, the question actually represents a circular argument, which is why it is utilized when people have a vested interest in preserving a status quo. Simply put, very few things work the first time, or even the second time.

I used to struggle with this question. We would go to the factory floor to try something and several people would fold their arms and say, “Well, let’s see if this works.” Of course within a short time the test failed. They were right, I was wrong, and the experiment would be over. At the first signs of problems, difficulties, or a failed step, it was announced that, “Well, that doesn’t work,” and often, “Let’s go back to the way we did it before because we know that works.”

Eventually it dawned on me how to deal with this question. Now, when arms fold up and people say, “Let’s see if this will work,” I say, “I can save you the time. We already know it probably won’t work.

Despite our best efforts to plan this, we know that within a short time there will be ‘charred and glowing pieces’ lying around. We just don’t know in advance when, where, or why it will fail.”

At this point the arms usually start unfolding a bit, and I follow with, “What we should be asking ourselves is not will it work, but, let’s see what we need to do to make this work.” After calibrating a group’s thinking in this way, I am always impressed with the smart ideas people from all levels come up with to get us closer to the target condition.

Toyota Is More Interested in What Does Not Go as Planned

The thinking reflected in Figure 6-8 is fundamental in Toyota’s improvement kata.

Interpretation: if there is no problem, or it is made to seem that way, then our company would, in a sense, be standing still. Toyota’s management wants the organization to see and utilize small problems in order to exploit the potential they reveal, and before they affect the external customer. If people are threatened by problems, then they will either hide them or conduct poor problem solving by quickly jumping to countermeasures without sufficiently analyzing and understanding the situation. The idea is to not stigmatize failures, but to learn from them.

To function in this way, the improvement kata should be depersonalized and have a positive, challenging, no-blame feeling. Toward that end, at Toyota an abnormality or problem is generally not thought of or judged good or bad, but as an occurrence that may teach us something about our work system. This can be somewhat difficult for westerners to understand: something can be a problem—a situation that we do not want—without it necessarily being considered good or bad. This is akin to the difference between “understanding” and “accepting.” Trying to understand a situation and why it happens does

“NO PROBLEM” = A PROBLEM

Figure 6-8. A different way of thinking

not mean you have to accept it. Making this distinction will make you a better problem solver. Interestingly, if you look up problem in the dictionary, you won’t find the negative connotation that we often assign to this word.

For example, at a Toyota assembly plant, I once was told that the normal number of andon pulls is typically around 1,000 per shift. Each pull is an operator calling for assistance from their team leader because the operator is experiencing a problem; a cross-threaded bolt here, a task that took a little too long there. Naturally, the number of andon pulls per shift varies, and I once heard of it dropping to only 700 pulls/shift. When I ask non-Toyota managers what they would do in this situation, I often get the answer, “We would celebrate the improvement.”

According to my source, what actually happened when the number of andon pulls dropped from 1,000 to 700 per shift is that the Toyota plant’s president called an all-employee meeting and said, “The drop in andon pulls can only mean two things. One is that we are having problems but you are not calling for help. I want to remind you of your responsibility to pull the andon cord for every problem. The other possibility is that we are actually experiencing fewer problems. But there is still waste in our system and we are staffed to handle 1,000 pulls per shift. So I am asking group leaders to monitor the situation and reduce inventory buffers where necessary so we can get back to 1,000 andon pulls per shift.” This is quite a contrast to our current thinking.

Another example came while touring a U.S. vehicle assembly plant in Detroit with a group that included a former Toyota executive. At one point the plant manager remarked proudly, “Our vehicle assembly line runs three shifts and it never stops.” To which the former Toyota executive responded with some irony, “Ah, they must all be perfect.”

We hear about Toyota’s successes, but not about its thousands of small failures that occur daily, which provide a basis for that success. Toyota makes hay of problems every day, where we tend to hide little problems until they grow into big and complex problems that are then difficult to dissect. Toyota has mastered the art of recognizing problems as they occur, analyzing their nature, and using what it learns to adapt and keep moving toward its target conditions.

Focusing On Process Instead of Blame

Toyota’s approach of not stigmatizing failures, but instead utilizing them to learn and move forward, has an interesting effect: thinking that an abnormality or problem is neither positive nor negative shifts the focus from the individual to the process. We know that the vast majority of problems are caused by the system within which people work, rather then by the individuals themselves. Therefore, Toyota maintains a no-blame focus on the process, instead of on the people around the problem. The assumptions are:

- People are doing their

- A problem is a system problem, and if we were the other person, the same problem would still have

- There is a reason for everything, and we can work together to understand the reason for a

An elegant question in this respect that I learned from Toyota is, “What is preventing the operators from working according to the standard?” I encourage you to utilize this question as you strive for a target condition, because it alters your thinking and changes where you look when a problem occurs.

Be hard on the process, but soft on the operators.

—Toyota

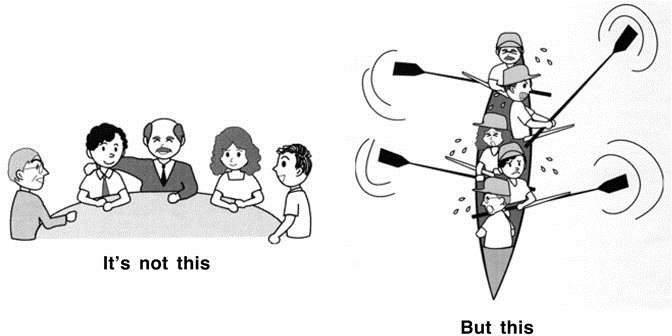

Note, however, that while an abnormality, problem, or unexpected result itself is not necessarily viewed as good or bad, and the system is considered the problem, Toyota does put intense and critical attention on both the problem and how people deal with it. Do we give it sufficient urgency and attention? Do we follow the improvement kata? We should not confuse Toyota’s “no blame” culture with an easygoing “no worries” culture, as depicted in Figure 6-9.

Figure 6-9. Not stigmatizing failures does not mean “no worries”